Unlocking Efficiency: The Transformative Benefits of the Best Mill Turn Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, the pursuit of efficiency is paramount. The advent of advanced machining technologies has revolutionized production processes, and among these innovations, the mill turn machine stands out as a game-changer. This remarkable equipment seamlessly integrates both milling and turning capabilities, drastically reducing setup times while enhancing precision. As manufacturers face increasing pressure to deliver high-quality products at competitive prices, the best mill turn machines are proving indispensable. They not only streamline operations but also enable companies to meet the rising demand for complex components with greater agility. In this blog, we will explore the transformative benefits of adopting mill turn machines in modern manufacturing, highlighting how these powerful tools are unlocking new levels of efficiency and performance across various industries. Join us as we delve into the critical role that these machines play in shaping the future of manufacturing.

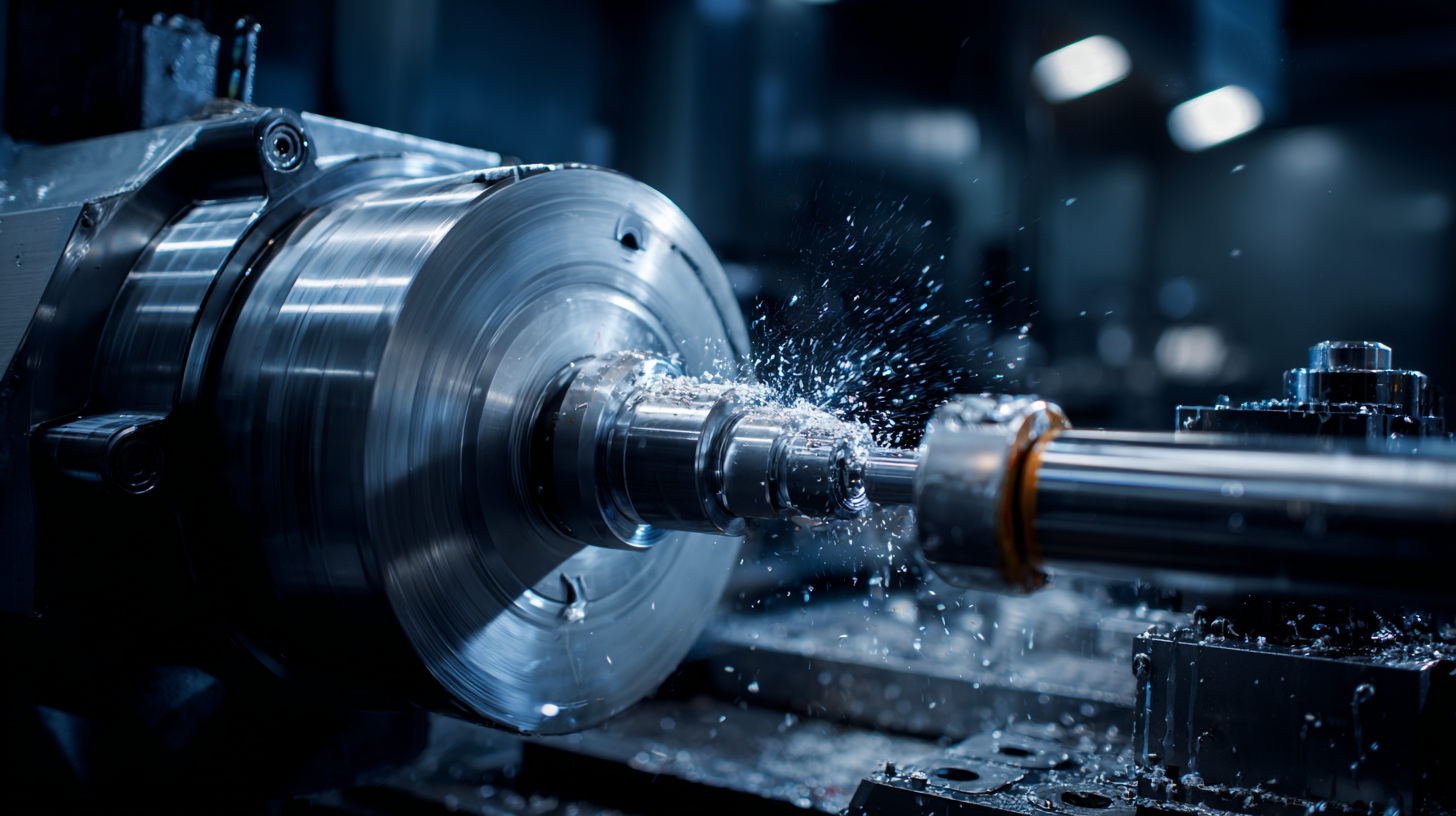

The Evolution of Mill Turn Machines in the Manufacturing Sector

The manufacturing sector has undergone a remarkable transformation with the evolution of mill turn machines. Initially designed for basic milling and turning operations, these machines have advanced into highly sophisticated equipment that integrates multiple functions into a single unit. This shift has enabled manufacturers to enhance precision and reduce cycle times while minimizing the need for manual intervention. As technology has progressed, features such as digital controls, automation, and advanced materials have become standard, allowing for more intricate and complex designs to be produced efficiently.

As industries evolve, the demand for versatility and adaptability in machine tools has driven the innovation of mill turn solutions. Manufacturers now benefit from machines that can seamlessly switch between turning, milling, and even grinding operations within one setup. This capability not only streamlines the production process but also leads to significant cost savings. Furthermore, the integration of smart technologies has introduced real-time monitoring and predictive maintenance, ensuring optimal performance and reduced downtime. The continuous advancements in mill turn machines reflect the manufacturing sector's commitment to improving efficiency and meeting the ever-growing demands of the market.

Unlocking Efficiency: The Transformative Benefits of Mill Turn Machines

This chart illustrates the efficiency gains in manufacturing processes through the adoption of mill turn machines over recent years.

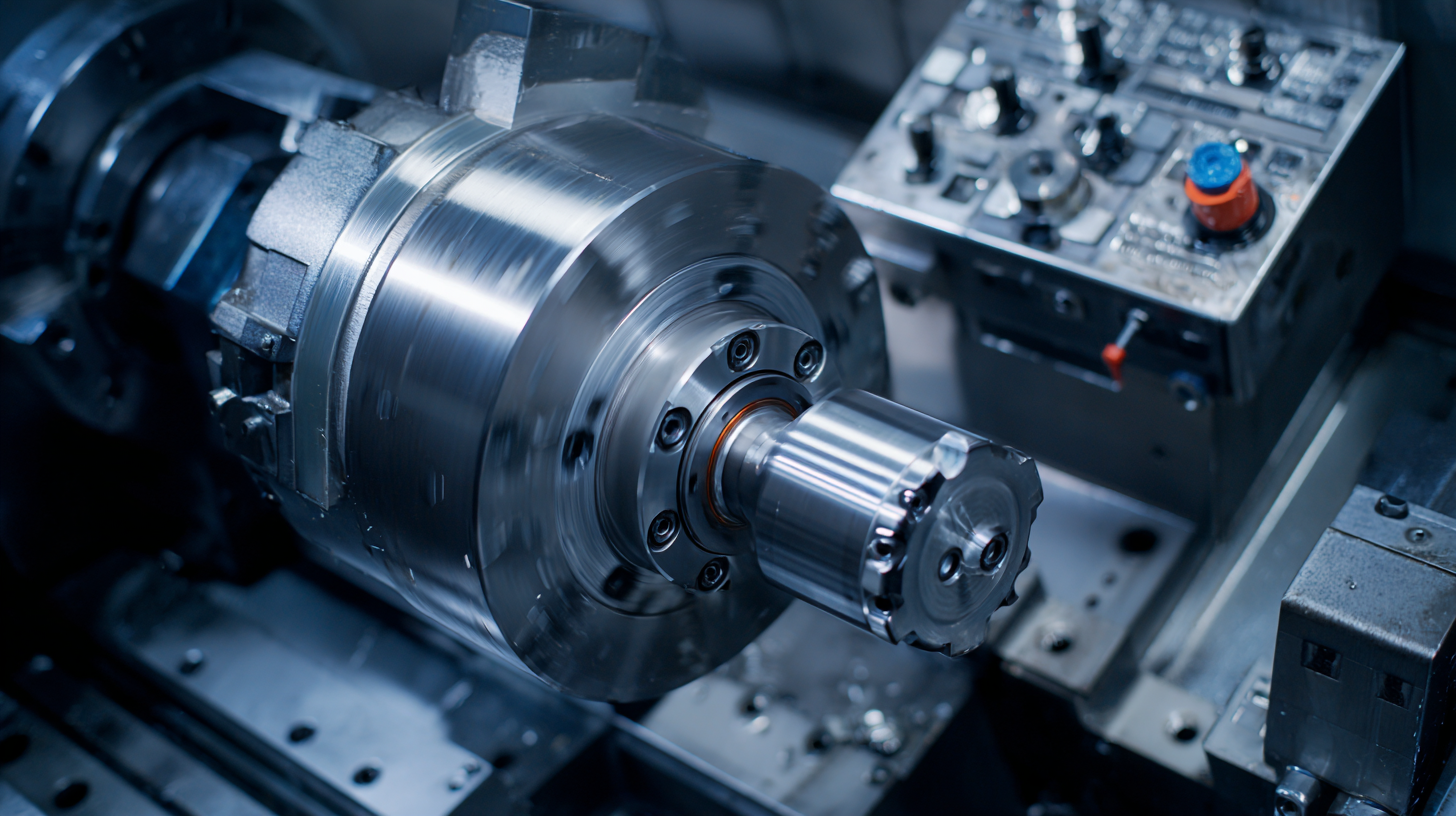

Key Features That Define the Best Mill Turn Machines Today

In the realm of modern manufacturing, the rise of mill turn machines has redefined productivity and precision. The best mill turn machines today are distinguished by several key features. First and foremost, multi-axis capabilities allow for intricate machining processes, increasing the variety of components that can be produced from a single setup. According to a report by Deloitte, manufacturers that utilize advanced machining technologies, including mill turn machines, can see productivity gains of up to 30%, making it an indispensable tool in competitive industries.

Another defining feature is the integration of automation and CNC technology. This innovation facilitates real-time data monitoring and adaptive machining, which not only enhances operational efficiency but also minimizes human error. A study published in the Journal of Manufacturing Science and Engineering highlighted that companies adopting such technologies experienced a 15% reduction in production costs.

**Tip:** When selecting a mill turn machine, look for models that offer comprehensive software support for programming and diagnostics. Investing in training for your team can also lead to better utilization of machine capabilities, maximizing your returns. Additionally, prioritize machines with enhanced tool change capabilities to further boost efficiency in high-volume production environments.

Unlocking Efficiency: The Transformative Benefits of the Best Mill Turn Machines in Modern Manufacturing

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Multi-Tasking Capability | Combines milling and turning processes in a single machine, reducing setup times and improving workflow. | Significantly reduces production cycle times by integrating tasks. |

| CNC Control | Computer Numerical Control allows for precise automation and repeatability in machining operations. | Enhances accuracy and reduces human error, leading to higher quality output. |

| Tooling Flexibility | Supports various types of tooling, enabling the machining of diverse materials and complex geometries. | Increases versatility and allows for the production of customized parts efficiently. |

| High-RPM Spindle | Equipped with high-speed spindles for faster machining operations. | Boosts productivity by reducing machining time for each part. |

| Automated Tool Change | Facilitates quick and efficient tool changes without manual intervention. | Minimizes downtime and maximizes operational efficiency during production. |

| Integrated Inspection Systems | On-machine measurement systems to ensure parts meet specifications during production. | Reduces scrap rates and rework by catching issues early in the machining process. |

How Mill Turn Machines Enhance Productivity and Efficiency

In contemporary manufacturing, the integration of mill turn machines has become pivotal in elevating productivity and efficiency. These versatile machines combine the capabilities of milling and turning into a single process, significantly reducing setup times and enhancing workflow. By streamlining operations, manufacturers can achieve higher output while minimizing waste, making mill turn machines an indispensable asset in modern manufacturing settings.

Tips for maximizing productivity with mill turn machines include optimizing tool paths and maintaining a rigorous maintenance schedule. Regularly updating the CNC programs to reflect the best practices in machining can dramatically improve cycle times. Additionally, investing in high-quality tooling can lead to smoother operations and longer tool life, ultimately reducing downtime.

Another essential tip is to train operators thoroughly on the capabilities and features of the mill turn machines. Skilled operators can leverage the machines’ advanced functionalities, such as simultaneous machining, to achieve complex geometries with greater precision. Emphasizing operator training not only enhances efficiency but also fosters a culture of continuous improvement within the manufacturing environment.

Navigating Industry Regulations: Import and Export Certifications for Machinery

When it comes to modern manufacturing, efficiency and compliance go hand in hand. As companies invest in the best mill turn machines to optimize their production processes, understanding industry regulations becomes crucial. Import and export certifications for machinery are not just bureaucratic hurdles; they are essential instruments that ensure safety, quality, and reliability in the global marketplace. Managers must navigate these certifications carefully to avoid costly delays and legal implications.

Obtaining the necessary certifications can seem daunting, but they provide a roadmap for manufacturers to comply with international standards. Certifications such as ISO, CE, and other specific local requirements can enhance a company’s credibility and market access. Moreover, understanding these regulations helps manufacturers select the right mill turn machines that meet compliance standards, ultimately leading to smoother operations and increased customer confidence. By prioritizing navigational strategies within industry regulations, businesses can streamline their manufacturing processes while fostering trust in their products.

Real-World Case Studies: Mill Turn Machines Transforming Manufacturing Operations

Mill turn machines have revolutionized the landscape of modern manufacturing, offering dynamic solutions that enhance both productivity and precision. Real-world case studies highlight their transformative impact across various industries. For instance, a leading aerospace manufacturer integrated mill turn machines into their workflow, resulting in a 30% reduction in machining time while maintaining stringent quality standards. This efficiency not only optimized their production schedule but also allowed them to meet tight delivery deadlines, a critical factor in the competitive aerospace market.

**Tip:** To maximize the benefits of mill turn machines, consider investing in employee training programs. Well-trained operators can harness the full potential of these machines, ensuring optimal settings for each task and reducing the likelihood of costly errors.

Another notable example comes from the automotive sector, where a company adopted mill turn technology to streamline the creation of complex components. This shift led to improved part integration and reduced assembly time by 25%. The ability to perform multiple operations in a single setup minimizes the need for tool changes, further accelerating production.

**Tip:** Regular maintenance is key to sustaining performance. Schedule routine checks to ensure that all components of the mill turn machine are in optimal condition, allowing for uninterrupted production and extending the life of the equipment.