Ultimate Guide to Sourcing Top Quality CNC Boring Mills: Tips for Global Buyers

In the rapidly evolving world of manufacturing, the demand for precision machinery has surged significantly, with the CNC boring mill taking center stage in this transformation. According to a recent market analysis report by Grand View Research, the global CNC machine market is projected to reach USD 100 billion by 2025, with a substantial share attributed to CNC boring mills due to their pivotal role in enhancing productivity and ensuring accuracy in heavy machining applications. The shift towards automation and the increasing complexity of manufacturing processes are driving global buyers to seek top-quality CNC boring mills that meet stringent specifications and offer cutting-edge technology. This ultimate guide aims to provide invaluable insights and practical tips for sourcing these essential machines, ensuring that buyers can navigate the international market effectively and make informed decisions to boost their operational capabilities.

Key Trends Shaping the CNC Boring Mill Market by 2025

The CNC boring mill market is undergoing significant transformation, driven by innovative technology and increasing demand for precision machining. With the global machining centers market valued at USD 29.17 billion in 2018 and projected to soar to USD 60.13 billion by 2032, companies must stay attuned to emerging trends that will shape their purchasing decisions. High-precision technologies are becoming indispensable as manufacturers seek operational efficiency and superior product quality.

To capitalize on this market growth, global buyers should focus on sourcing equipment that meets the evolving demands of their applications. Tip 1: When evaluating CNC boring mills, prioritize vendors that offer robust support and service networks, ensuring timely maintenance and minimizing downtime. Tip 2: Consider the scalability of the machines; future-proofing your investment with modular designs can enhance flexibility as production needs change.

Additionally, as players in the industry look to adapt to new market realities, understanding geographic trends will be crucial. By 2025, we expect substantial growth in regions that are investing in advanced manufacturing sectors, emphasizing the need for a strategic approach when sourcing high-precision boring mills.

Understanding the Different Types of CNC Boring Mills for Global Buyers

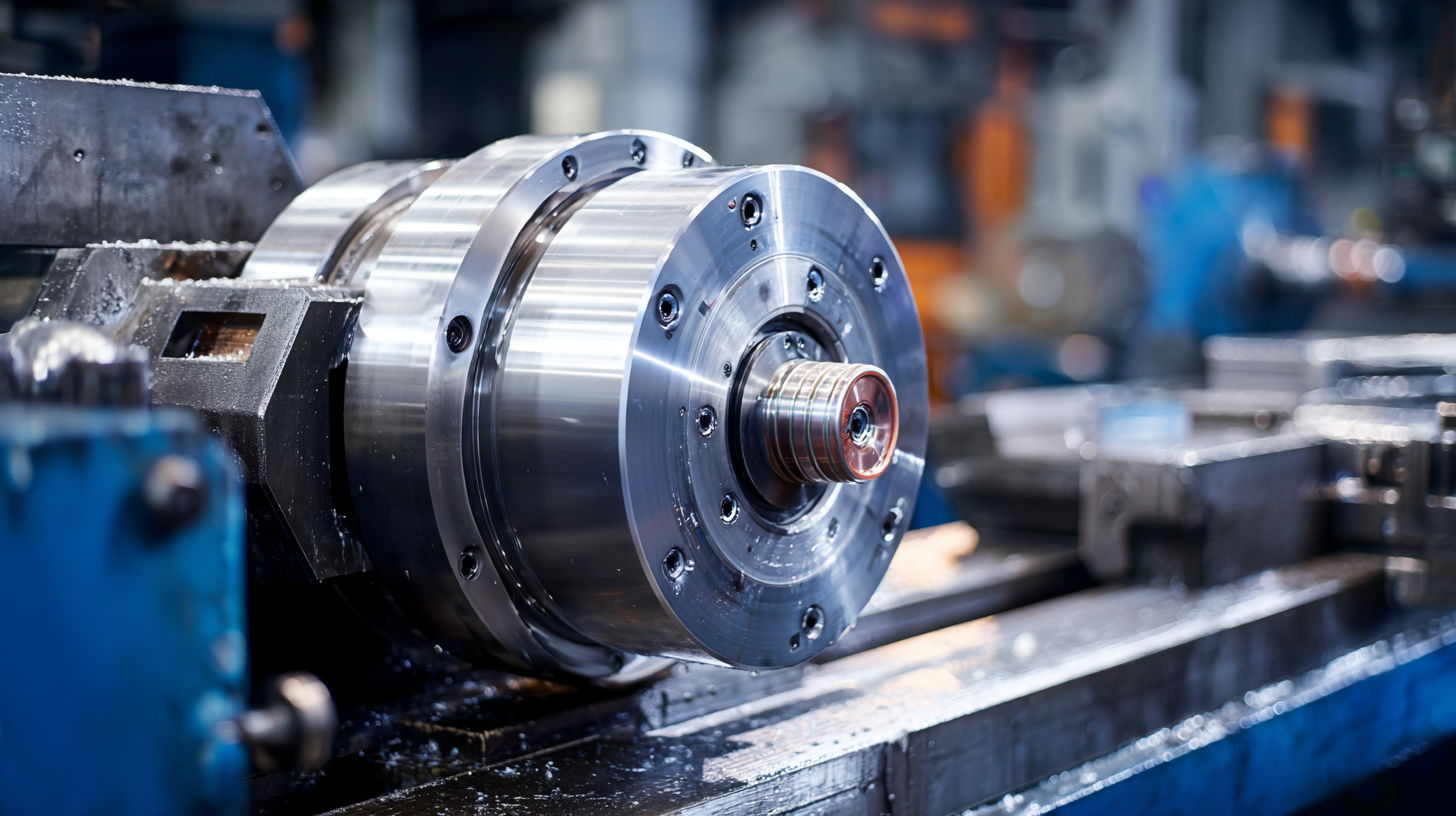

When sourcing CNC boring mills, understanding the various types available is crucial for global buyers looking to make informed purchasing decisions. CNC boring mills can be classified into several categories based on their design and function. For instance, there are vertical boring mills, which excel in precision machining for larger parts, and horizontal boring mills, ideal for complex, heavy-duty operations. Each type offers unique benefits, making it essential for buyers to assess their specific needs and the types of materials they will be working with.

When sourcing CNC boring mills, understanding the various types available is crucial for global buyers looking to make informed purchasing decisions. CNC boring mills can be classified into several categories based on their design and function. For instance, there are vertical boring mills, which excel in precision machining for larger parts, and horizontal boring mills, ideal for complex, heavy-duty operations. Each type offers unique benefits, making it essential for buyers to assess their specific needs and the types of materials they will be working with.

Moreover, as the global CNC market is poised for substantial growth—projected to double in size by 2032—buyers must stay ahead of the trends in CNC technology. Investing in quality CNC boring mills not only enhances productivity but also positions businesses to capitalize on emerging opportunities in the industry. Understanding different CNC boring mill configurations helps buyers select equipment that aligns with their operational goals, ensuring they are well-prepared to navigate the expanding market landscape effectively.

Quality Assessment: Key Features to Look for in CNC Boring Mills

When sourcing top-quality CNC boring mills, quality assessment becomes paramount. Key features to scrutinize include machining accuracy, rigidity, and temperature stability. A scientific understanding of machinability reveals that factors such as tool selection and process planning directly impact the final product's quality. For instance, data indicates that CNC machines with advanced thermal stability can maintain precision even under varying operational temperatures, thus reducing unwanted variations in machined components. This aspect is critical in high-stakes industries like aerospace, where the assembly processes of components such as aircraft horizontal stabilizers require stringent quality control to ensure safety and performance.

Moreover, incorporating deep learning technologies in evaluating CNC boring mills can enhance quality assessment. Recent studies highlight the application of novel neural network models to assess the quality of machined parts by rejecting external noise and delivering real-time feedback. This methodology can significantly improve consistency and process efficiency in machining operations. Employing modern evaluation techniques can ultimately streamline the sourcing process for global buyers by distinguishing exceptional quality machines from their lesser counterparts, thereby ensuring better returns on investment.

Ultimate Guide to Sourcing Top Quality CNC Boring Mills: Tips for Global Buyers

| Key Features | Specifications | Importance |

|---|---|---|

| Spindle Speed | Up to 6000 RPM | Essential for efficiency in boring operations |

| Table Size | 2000mm x 1000mm | Critical for handling various workpiece sizes |

| Cutting Tool Compatibility | ISO 40 | Affects versatility in machining operations |

| Accuracy | ±0.01mm | Necessary for precision engineering tasks |

| Control System | CNC interface with G-code | Important for automation and programming |

| Weight Capacity | Up to 5000 kg | Vital for large component machining |

| Coolant System | Flood coolant with filtration | Enhances tool life and machining efficiency |

Top Global Manufacturers: Who to Trust in the CNC Boring Mill Market

When navigating the CNC boring mill market, identifying trustworthy manufacturers is crucial for global buyers seeking top-quality machinery. A few industry leaders have established their reputation through innovation, reliability, and exceptional customer service. Brands like DMG Mori and Haas Automation stand out as pioneers, combining cutting-edge technology with robust engineering to meet diverse machining needs. Their commitment to quality ensures that buyers receive not only a machine but also a comprehensive service package that includes support and maintenance.

When navigating the CNC boring mill market, identifying trustworthy manufacturers is crucial for global buyers seeking top-quality machinery. A few industry leaders have established their reputation through innovation, reliability, and exceptional customer service. Brands like DMG Mori and Haas Automation stand out as pioneers, combining cutting-edge technology with robust engineering to meet diverse machining needs. Their commitment to quality ensures that buyers receive not only a machine but also a comprehensive service package that includes support and maintenance.

Additionally, emerging players from Asia, such as Yamazaki Mazak and JTEKT, are gaining traction by offering high-performance CNC boring mills at competitive prices. These manufacturers prioritize advancements in automation and precision, making them appealing options for buyers looking to enhance their production capabilities. Engaging with these established firms ensures that buyers can trust the integrity and performance of their investment, ultimately leading to improved efficiency and output in their manufacturing processes.

Cost Considerations: Budgeting for High-Quality CNC Boring Mills

When considering the purchase of high-quality CNC boring mills, cost is a critical factor that global buyers must carefully evaluate. The projected growth of the deep hole drilling machines market, which is expected to expand from USD 911.07 million in 2025 to USD 1507.82 million by 2033, underscores the increasing demand for precision machinery. This rise indicates not only an expanding market but also signifies the importance of investing in quality equipment that stands the test of time.

Budgeting for such machinery involves more than just the initial purchase price. Rebuilding a CNC machine, while costly, can often provide superior performance compared to new models. It requires skilled craftsmanship and a clear understanding of the required upgrades, ensuring that the investment leads to enhanced operational efficiency and output quality. Buyers should weigh these factors carefully, considering the long-term benefits of high-quality and possibly refurbished machines against immediate costs, to make informed decisions that support their production goals.