The Future of Precision: Advancements in Best CNC Machining Centers

In today's rapidly evolving manufacturing landscape, the importance of CNC machining centers cannot be overstated. As per a recent report by Grand View Research, the global CNC machine market is projected to reach USD 100.3 billion by 2028, driven by a growing demand for precision manufacturing across various industries. China's manufacturing sector, often hailed as the "world's factory," is increasingly focusing on quality to earn global respect. This paradigm shift is evident in the strategic advancements being made in CNC machining technology.

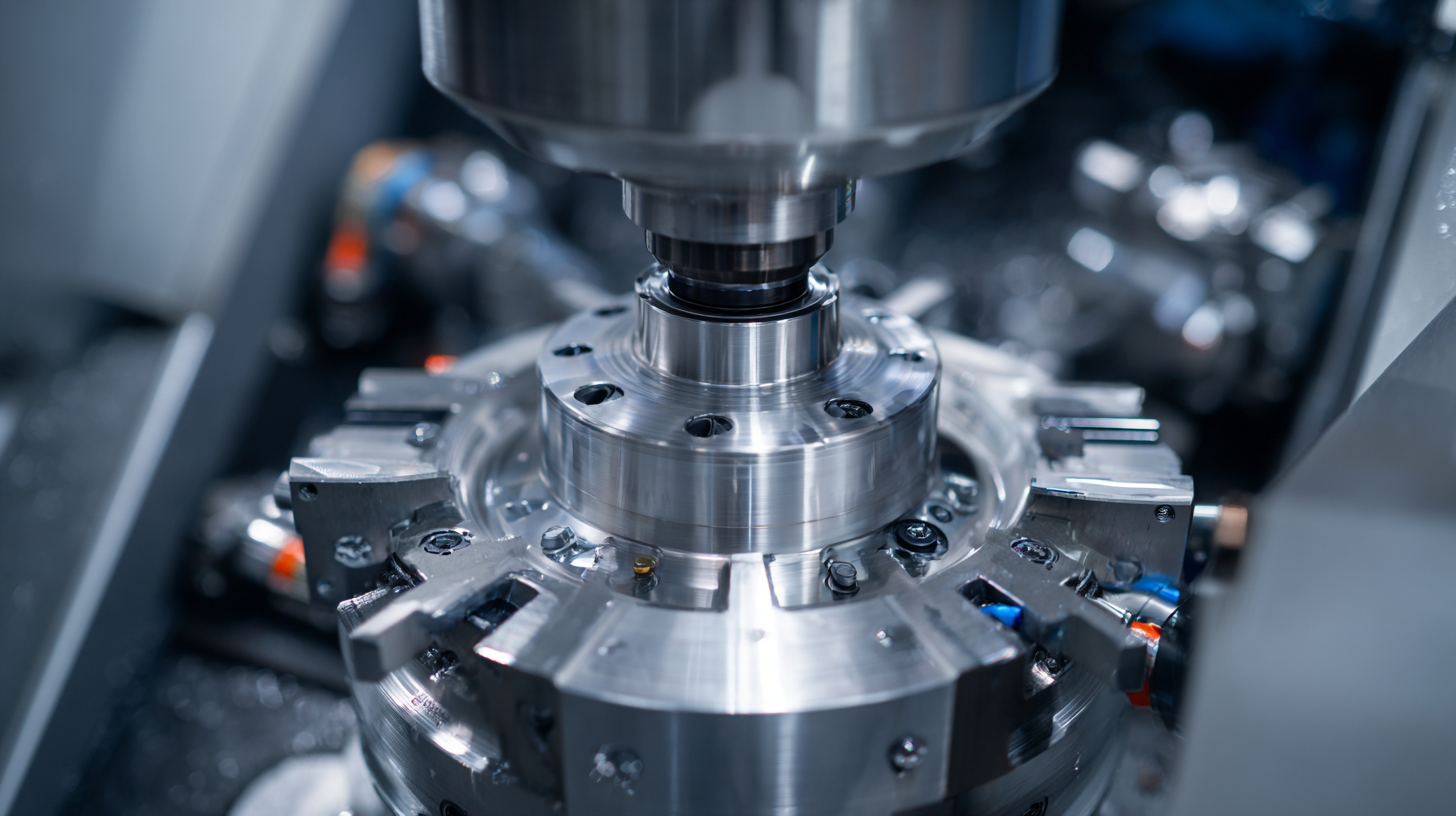

With innovations in automation, software integration, and material usage, CNC machining centers are not only enhancing efficiency but also elevating the standards of precision engineering. As we explore the future of these vital tools, it becomes clear that their role in ensuring high-quality production is paramount in retaining competitive advantage and meeting the rising expectations of a discerning global market.

Key Features to Look for in Modern CNC Machining Centers

The modern CNC machining center is evolving rapidly, driven by technological advancements that enhance precision and efficiency. As the global horizontal machining center market is projected to grow from $5.44 billion in 2023 to $7.2 billion by 2032, key features in contemporary machines are gaining increasing importance. Manufacturers should prioritize high-speed machining capabilities, which can significantly reduce production times while maintaining accuracy and surface finish quality.

Another critical aspect to consider is automation. The recent patent granted for an "automatic machining device" underscores the industry's shift towards fully automated solutions. Machines equipped with advanced features not only streamline production but also minimize human error, ensuring consistency in output. Furthermore, innovations in multi-axis machining allow for complex part geometry to be processed in a single setup, thereby enhancing efficiency and reducing the need for multiple fixtures.

In addition, developments such as mobile processing centers indicate a trend towards adaptability in production environments. The introduction of compact units capable of processing large volumes underscores the shift away from traditional fixed installations, catering to the needs of diverse applications. As these trends unfold, manufacturers must stay informed about emerging technologies and invest in CNC machining centers that incorporate these cutting-edge features.

Top Brands Leading the Way in Precision CNC Technology

The landscape of precision CNC technology is rapidly evolving, led by several top brands renowned for their commitment to innovation and quality. Recent analyses suggest that the CNC machine market is projected to see substantial growth, with significant advancements anticipated in various sectors including automotive, aerospace, and industrial manufacturing. According to market research, these industries are prime drivers for CNC technology, with an expected growth rate that highlights the increasing demand for precision engineering solutions.

In a strategic move to consolidate expertise in precision machining, major players have recently united under a new banner, signaling a pivotal shift in the industry. The merger is expected to enhance capabilities, streamline production processes, and foster advancements in cutting-edge technologies. As companies continue to integrate digital manufacturing technologies and explore trends like additive manufacturing, the CNC sector is poised for transformative improvements in efficiency and productivity. By focusing on these innovations and the significant contributions from leading brands, the future of precision machining reveals a promising horizon filled with potential breakthroughs.

Essential Software Solutions Enhancing CNC Machining Efficiency

The future of CNC machining is being transformed by essential software solutions that enhance efficiency and accuracy. As the manufacturing sector embraces advanced technologies, artificial intelligence (AI) plays a pivotal role in optimizing processes. The introduction of self-optimized machine cutting techniques is positioning 5-axis CNC machining centers for significant growth, with projections suggesting an increase of USD 792.5 million from 2024 to 2028. AI's integration into CNC machining not only streamlines operations but also boosts the precision of manufacturing capabilities.

Another critical advancement in this space is the concept of digital twins. By creating virtual representations of physical objects, manufacturers can monitor performance, predict maintenance needs, and optimize workflows in real time. This technology allows for a deep understanding of machine behavior, ultimately leading to more efficient operations. As robotics and AI continue to evolve, they will redefine how we view production environments, ensuring manufacturers maintain a competitive edge while meeting growing demands for precision and quality.

The Future of Precision: Advancements in Best CNC Machining Centers - Essential Software Solutions Enhancing CNC Machining Efficiency

| CNC Machining Center Model | Max Speed (RPM) | Work Envelope (mm) | Control Software | Efficiency Rating |

|---|---|---|---|---|

| Model A | 10,000 | 600 x 400 x 300 | Software X | 95% |

| Model B | 12,000 | 800 x 600 x 400 | Software Y | 90% |

| Model C | 15,000 | 1000 x 800 x 600 | Software Z | 92% |

| Model D | 14,000 | 700 x 500 x 350 | Software W | 88% |

Maintenance Checklist for Optimizing CNC Performance

Maintaining optimal performance in CNC machining centers is crucial for enhancing precision and prolonging the lifespan of the equipment. A well-structured maintenance checklist can help operators systematically address various aspects of their machines. Start with routine inspections, focusing on the condition of the spindle, guideways, and tooling. Regularly checking for any signs of wear or damage can prevent costly repairs and ensure consistent performance.

Next, lubrication plays a vital role in the smooth operation of CNC machines. Ensure that all moving parts are adequately lubricated according to the manufacturer's specifications. This includes checking oil levels and replacing any old or contaminated lubricant. Additionally, keep a close eye on the cooling system, as overheating can lead to serious issues. Regular cleaning of filters and coolant exchange helps maintain the efficiency of the cooling system, which is essential for precision machining.

Lastly, software updates and calibration should not be overlooked. Keeping the CNC software up-to-date can introduce new functionalities and improve overall efficiency. Periodic calibration of the machine ensures that it maintains the desired accuracy, preventing deviations that could affect the quality of the finished product. By following these maintenance practices, operators can achieve enhanced performance and productivity from their CNC machining centers.

The Future of Precision: CNC Machining Centers Performance Metrics

Future Trends in CNC Machining: What to Expect in the Next Decade

The CNC machining industry is poised for significant transformation over the next decade, driven by advancements in technology and evolving market demands. According to a report by MarketsandMarkets, the global CNC machine market is expected to grow from $67.5 billion in 2021 to $116.5 billion by 2026, at a compound annual growth rate (CAGR) of 11.3%. This growth is largely attributable to the increasing adoption of automated CNC solutions, which enhance precision and efficiency, reducing production costs for manufacturers across various sectors.

As we look to the future, trends such as the integration of artificial intelligence and machine learning into CNC machining processes are expected to reshape traditional practices. A study from Deloitte indicates that around 30% of manufacturing companies are embracing AI-driven analytics to optimize their machining operations, facilitating real-time data processing and predictive maintenance. Additionally, the rise of IoT-enabled CNC machines will enable unprecedented connectivity, allowing for smarter factories where machines can communicate and adapt autonomously to changing conditions. The convergence of these technologies promises to not only enhance precision in CNC machining but also redefine operational paradigms for manufacturers worldwide.