Ultimate Checklist for Selecting the Best CNC Turning Machine for Your Business

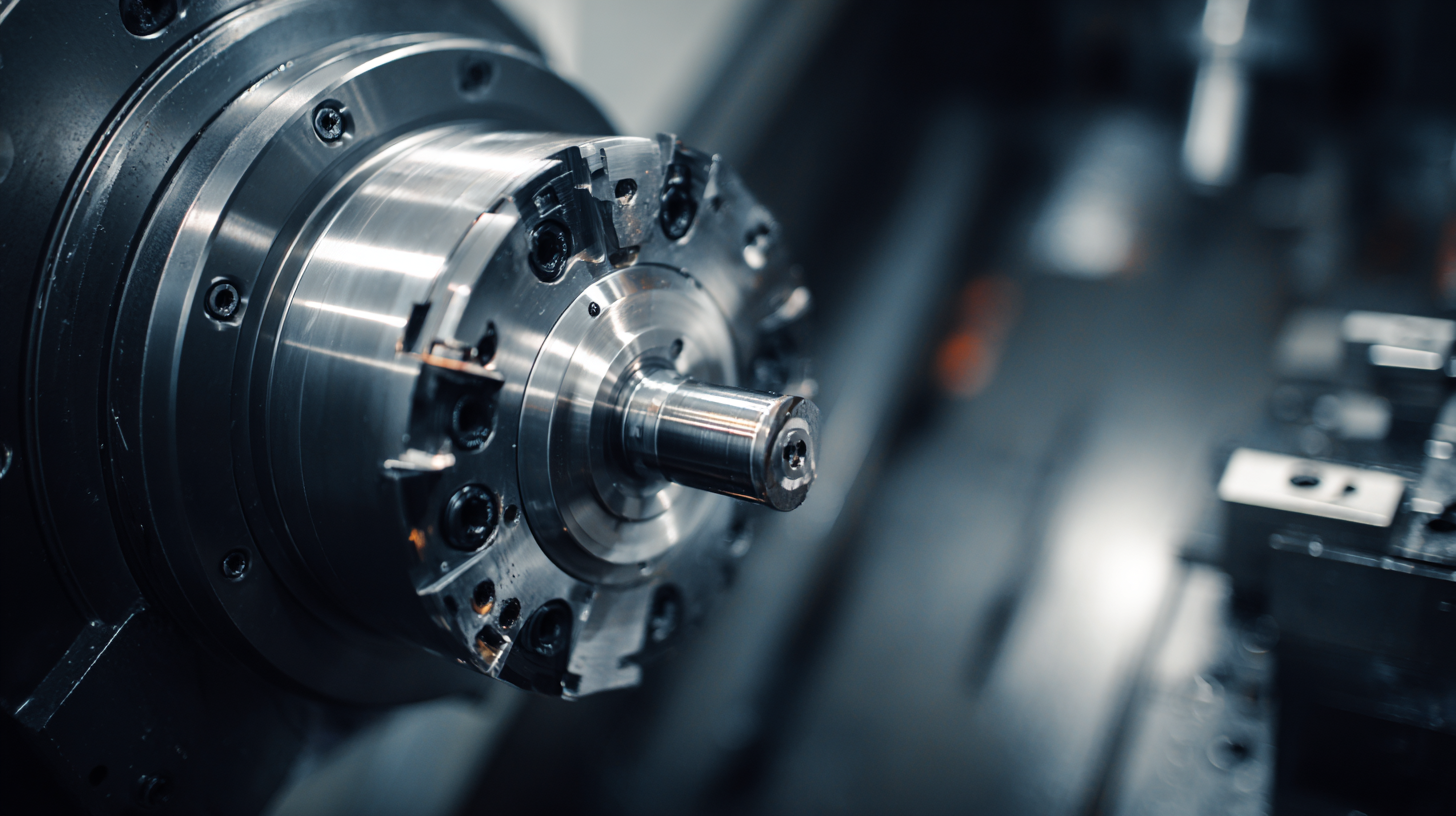

In today's rapidly evolving manufacturing landscape, selecting the right CNC turning machine is crucial for businesses seeking to enhance their productivity and maintain a competitive edge. With a focus on quality and a commitment to excellence, Chinese manufacturers have become global leaders in producing high-performance CNC turning machines that cater to diverse industrial needs.

This ultimate checklist aims to guide business owners through the essential considerations and features they should evaluate when choosing a CNC turning machine. From precision and durability to technological advancements and export capabilities, understanding these factors can significantly influence production outcomes and overall efficiency. Join us as we navigate through the vital aspects that define the best CNC turning machines available today, ensuring your business makes an informed investment that supports its growth and success.

Understanding Your Business Needs for CNC Turning Machines

When selecting the best CNC turning machine for your business, understanding your specific operational needs is paramount. A thorough assessment of your production requirements, such as part complexity, volume, and precision, will guide your choice. For instance, industries like aerospace and defense often necessitate mastering complex precision machined parts, which demand advanced CNC capabilities. Meanwhile, the rise of automation technologies can enhance productivity and efficiency, making these features crucial when investing in a new machine.

Additionally, as the CNC machinery market continues to grow, with projections estimating significant increases in market value, businesses must be strategic about their investment. An integrated approach that combines precision machining with cutting-edge automation solutions can lead to a competitive advantage. Furthermore, with the increasing connectivity of CNC machines in industrial environments, safeguarding these assets from cyber threats is essential. Assessing their compatibility with network security measures should also be part of your decision-making process to ensure long-term performance and reliability.

Ultimate Checklist for Selecting the Best CNC Turning Machine

Key Features to Look for in High-Quality CNC Turning Machines

When selecting a CNC turning machine for your business, understanding the key features that contribute to high-quality performance is essential. As the global CNC machinery market is projected to grow from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%, investing in the right equipment becomes pivotal for maintaining a competitive edge.

One critical feature to examine is spindle speed, as it directly influences the machining efficiency and finish quality. Machines capable of high RPM allow for faster cutting rates, thus increasing productivity and reducing cycle times. Another vital aspect is accuracy; superior CNC turning machines should offer exceptional precision, often within a range of ±0.001 inches. This precision ensures consistent product quality, which is crucial for businesses relying on intricate designs and tight tolerances. Lastly, consider the machine's tooling options and flexibility; the ability to handle various materials and maintain various tooling setups significantly impacts operational versatility and effectiveness.

Evaluating Manufacturer Reputation and Experience

When selecting the best CNC turning machine for your business, evaluating the manufacturer's reputation and experience is crucial. A well-established manufacturer typically demonstrates a history of reliability and quality. Look for companies with years of experience in the CNC industry, as this often correlates with a deeper understanding of technology advancements and customer needs. Manufacturers with a strong reputation often have a portfolio of satisfied clients, positive reviews, and case studies showcasing their successful projects. This credibility can provide peace of mind that you are investing in a technology partner that stands behind its products.

Additionally, consider the manufacturer's commitment to ongoing support and innovation. A reputable company not only sells machines but also invests in training and customer service. Inquire about technical assistance, maintenance services, and warranty options. An experienced manufacturer will likely have a team of experts readily available to help you optimize machine performance and minimize downtime. By prioritizing manufacturers with proven expertise and strong support systems, you can ensure that your investment in a CNC turning machine will yield the desired results for your manufacturing goals.

Ultimate Checklist for Selecting the Best CNC Turning Machine for Your Business - Evaluating Manufacturer Reputation and Experience

| Criteria | Description | Rating (1-5) | Comments |

|---|---|---|---|

| Manufacturer Experience | Years in business, industry expertise | 4 | Reliable with 20+ years in CNC machining |

| Customer Reviews | Feedback from previous customers | 5 | Highly rated by users, excellent support |

| Quality Certifications | ISO, CE certifications | 4 | ISO 9001 certified for quality management |

| After-Sales Service | Support and maintenance services offered | 5 | 24/7 support available, fast response times |

| Technology Integration | Compatibility with existing systems | 3 | Limited compatibility with older systems |

| Price Competitiveness | Cost-effectiveness compared to peers | 4 | Offers good value for high-end features |

The Importance of Customer Support and After-Sales Service

When selecting the best CNC turning machine for your business, prioritizing customer support and after-sales service is crucial. A reliable manufacturer not only provides high-quality machines but also stands by their products with robust support services. The ability to access timely assistance can significantly minimize downtime, ensuring your operations run smoothly and efficiently.

Tip: Before making a purchase, research the manufacturer's reputation for customer support. Look for reviews or testimonials from other users to gauge their experiences.

Moreover, after-sales service is vital in maintaining the performance of your CNC machine. A good support team should offer training for your staff, regular maintenance checks, and quick access to spare parts when needed. This proactive approach can prolong the life of the machine and enhance overall productivity.

Tip: Inquire about the warranty and support duration offered by the manufacturer. Choosing a company that commits to long-term service can save you money and hassle in the long run.

Cost Considerations: Balancing Quality and Budget for CNC Machines

When selecting a CNC turning machine for your business, cost considerations play a crucial role in ensuring that you strike the right balance between quality and budget. According to industry reports, businesses often face challenges in managing their capital expenditure while still needing to invest in high-quality machinery. For instance, a survey of manufacturing sectors revealed that about 60% of companies consider total cost of ownership—factoring in maintenance, repairs, and energy efficiency—when selecting CNC machines.

Budgeting for a CNC machine requires analyzing not just the initial purchase price, but also the long-term implications of your investment. A study highlighted that higher-quality CNC machines, while more expensive upfront, can reduce operational costs significantly due to lower failure rates and more efficient performance. In fact, companies reported that investing in machines with advanced features led to up to a 30% reduction in production time over several months. Therefore, businesses must evaluate their specific needs against the backdrop of these data insights, allowing for informed decision-making that aligns with both their financial constraints and operational goals.