Ultimate Checklist for Choosing the Best Machining Tools for Your Workshop

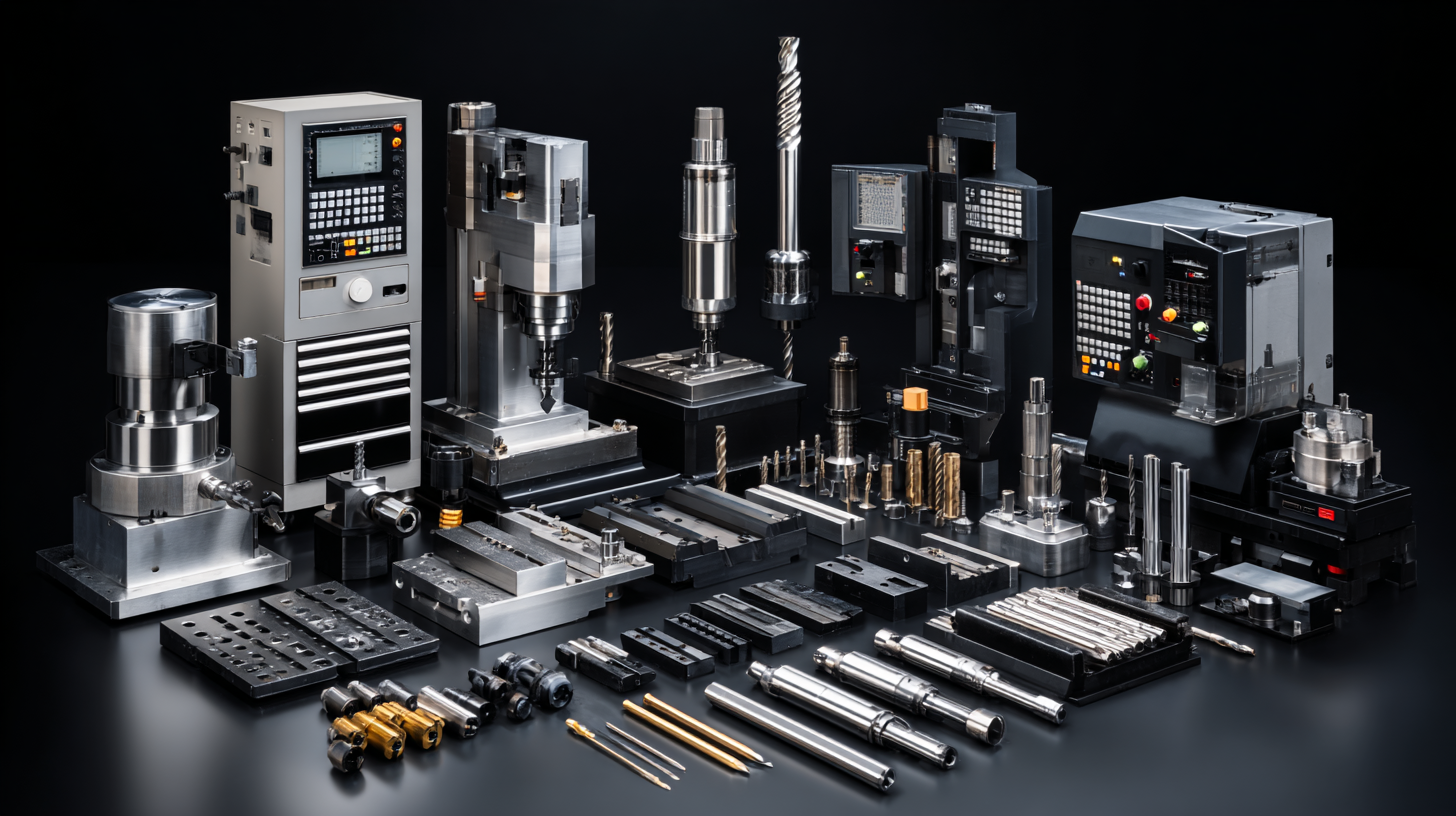

In the world of metalworking and fabrication, selecting the right machining tools is paramount to achieving precision and efficiency in your workshop. Whether you are a seasoned machinist or a newcomer to the trade, the process of choosing high-quality machining tools can be daunting. This ultimate checklist not only highlights key factors to consider when evaluating tools, but also guides you on how to find reliable suppliers who can provide the best options for your needs.

From understanding the types of machining tools available to assessing their compatibility with your projects, this blog will serve as a comprehensive resource to ensure you make informed decisions. By following these steps, you can elevate your workshop's capabilities and enhance your overall productivity.

Essential Features to Look for in Machining Tools

When choosing machining tools for your workshop, it’s crucial to focus on essential features that can greatly enhance your efficiency and output. Firstly, consider the material compatibility of the tools. Different projects may require specialized tools designed for specific materials such as aluminum, steel, or composites. Tools that offer versatility can save time and money, ensuring you have the right equipment at hand for various tasks.

Another key feature to look for is the precision and accuracy of the tools. High-quality machining tools should provide consistent results, which is vital for maintaining the integrity of your projects. Look for tools equipped with advanced technology, such as digital readouts or programmable settings, to enhance their precision. Additionally, the ease of use and ergonomic design should not be overlooked; tools that are comfortable to handle can significantly reduce fatigue and improve productivity during long working hours. By focusing on these essential features, you can select the best machining tools that will elevate your workshop performance.

Types of Machining Tools and Their Unique Advantages

When setting up a workshop, understanding the various types of machining tools and their unique advantages is crucial for achieving efficient and precise results. One of the primary categories is lathes, which are indispensable for turning and shaping materials. Lathes allow for a high degree of accuracy and can be used for a variety of tasks, from simple cylindrical shapes to complex designs. Their versatility makes them an essential choice for both hobbyists and professional machinists.

Another significant tool is the milling machine, renowned for its ability to produce complex parts with intricate detailing. Unlike lathes, which primarily work on rotational materials, milling machines use rotary cutters to remove material in a linear fashion, making them ideal for creating precise slots, holes, and irregular surfaces. This functionality offers machinists the flexibility to work with a wide range of materials, enhancing their productivity and enabling them to tackle diverse projects with ease. Understanding these tools and their specific advantages can help you make informed choices for a highly efficient workshop setup.

Ultimate Checklist for Choosing the Best Machining Tools for Your Workshop

How to Evaluate the Durability of Machining Tools

When evaluating the durability of machining tools for your workshop, it’s essential to consider the materials and construction quality. High-quality steel or carbide construction generally indicates a longer lifespan and better performance under stress. Additionally, check for surface treatments like coatings that enhance wear resistance, which can significantly extend the tool's operational life.

Here are some tips to help you choose the right tools: First, look for tools that come with a warranty or guarantee. This reflects the manufacturer's confidence in their durability. Second, consider user reviews and professional recommendations, as they provide real-world insights into a tool’s longevity. Finally, assess the maintenance requirements; tools that are easy to maintain will often have a longer lifespan and better functionality.

By taking the time to evaluate these factors, you can ensure that your workshop is equipped with reliable machining tools that will enhance your productivity and efficiency for years to come. With the global market for metal cutting tools projected to grow substantially, investing in durable equipment now will pay off in the long run.

Ultimate Checklist for Choosing the Best Machining Tools for Your Workshop - How to Evaluate the Durability of Machining Tools

| Tool Type | Material | Durability Rating | Maintenance Frequency | Typical Lifespan |

|---|---|---|---|---|

| CNC Milling Machine | Cast Iron | High | Monthly | 10-15 years |

| Lathe Machine | Steel | Medium | Quarterly | 8-12 years |

| Surface Grinder | Aluminum | High | Bimonthly | 10-20 years |

| Drill Press | Plastic | Medium | Yearly | 5-10 years |

| Band Saw | Carbon Steel | Low | Biannual | 3-7 years |

Cost-Effective Machining Tools: Balancing Quality and Budget

When it comes to setting up an efficient workshop, selecting cost-effective machining tools is crucial for any machinist. According to a report by Grand View Research, the global machine tools market is expected to reach approximately $200 billion by 2028, with a compound annual growth rate (CAGR) of about 6%. This statistic underscores the growing importance of optimizing both performance and budget in tool selection. By investing in high-quality yet affordable tools, workshops can maintain competitive advantages without compromising on precision and durability.

To strike the right balance between quality and cost, consider tools that provide reliable performance while being budget-friendly. Industry studies indicate that organizations favor brands with a reputation for longevity and efficiency. For example, a survey by Machine Tool Technology highlighted that over 75% of respondents prioritize tool longevity over initial purchase costs. When evaluating options, focus on tools with favorable reviews and endorsements in the machining community, as these often yield a better return on investment. By making informed choices, workshop owners can enhance their productivity while keeping costs manageable.

Safety Considerations When Selecting Machining Tools

When selecting machining tools for your workshop, safety should be your paramount consideration. A recent report highlights that the global CNC machine tools market is projected to grow by USD 21.9 billion between 2025 and 2029, chiefly driven by the rising demand for high-precision and multi-axis machining centers. As the capabilities of these tools expand, so too do the safety risks associated with their use. Proper safety guidelines, including the use of personal protective equipment (PPE), should be established to mitigate these risks while performing machining operations.

Tip: Always ensure that your workspace is well-ventilated and that you have emergency procedures in place, including first-aid kits and safety instructions readily available.

Furthermore, toolholder considerations are critical when working with heavier machinery. The compatibility of toolholders with the machine and cutting tools is essential for process reliability and safety. Training operators on the correct usage and maintenance of these tools can further enhance safety protocols in the workplace.

Tip: Regularly inspect and maintain your machining tools to prevent malfunction and accidental injuries.